Manufacturing Process and Material Selection of AllAluminum Easy Open Can Tin Can Making

According to the Environmental Protection Agency, more than half of aluminum soda and beer cans are recycled in the U.S. compared to only 31.2% of plastic beverage containers and 39.5% of glass containers. Cans also present an advantage in their convenience and portability for an increasingly active, on-the-go lifestyle.

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

Additional information on carbonated soft drinks containers includes: Name and address of the manufacturer, packer or distributor.; The "net quantity," or the amount of carbonated soft drink.

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

A beverage can or (a drink can) is a metal container manufactured to hold a single serving portion of liquid such as alcoholic drinks, carbonated soft drinks, fruit juices, energy drinks, teas, herbal teas, etc. What is the structure of beverage cans?

Beverage Cans, Aluminium Cans, Textured, Gloss or Matte Finish

In Golden, where manufacturing and storage operations span 500,000 square feet, aluminum beverage cans are formed, tested and labeled with the names and logos of brands familiar to consumers shoppi…

Many Aluminium Soda Drink Cans. Advertising for Soda Drinks or Tin Cans Mass Manufacturing Stock

What We Do. Vobev is the first company in North America to bring can-making, filling, and shipping into one full-service facility. That means less time spent managing vendors, more reliable shipments, and big cost savings for our partners.

Premium Photo Many new aluminium cans of soda soft drink or energy drink containers drinks

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright.

Beverage Can Manufacturing Process Aluminium Metals

Are you a company in the beverage industry? Comac Group manufactures modular soda plants that can be customized to fit in your business size and needs. A soda plant is basically the sum of two different machines: Soda making machine: to flavor and syrup to the original beverage and carbonate it

Premium Photo Many aluminium soda drink cans. advertising for soda drinks or tin cans mass

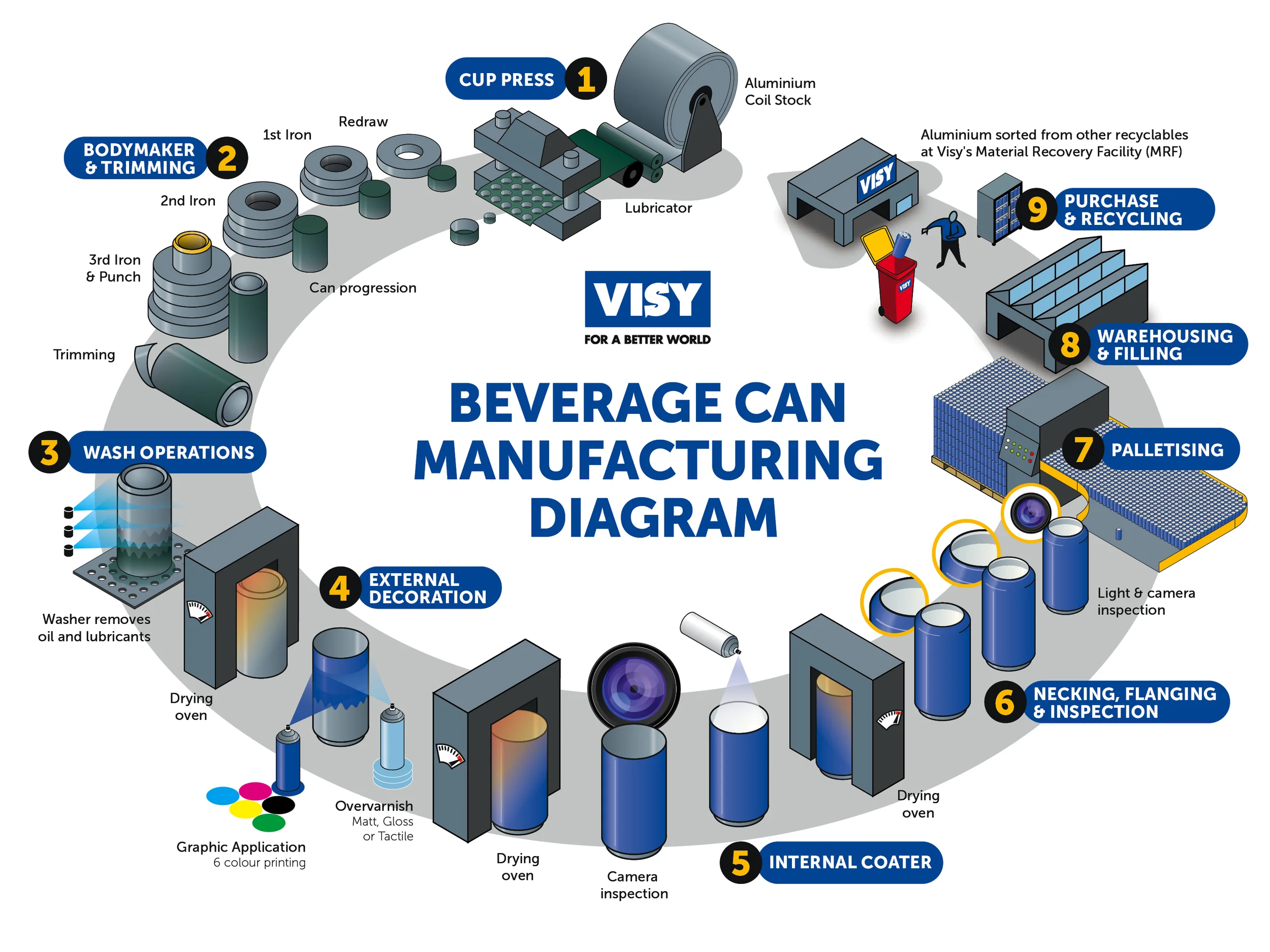

Manufacturing of soda cans omar khaled The aluminum beverage can is made with two pieces -the can body and the can end (or lid). The manufacturing process starts with coils of aluminum. Can plants use mass quantities of aluminum coil every day to make can bodies or ends.

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

A drink can (or beverage can) is a metal container designed to hold a fixed portion of liquid such as carbonated soft drinks, alcoholic drinks, fruit juices, teas, herbal teas, energy drinks, etc. Drink cans are made of aluminum (75% of worldwide production) [1] or tin-plated steel (25% worldwide production).

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

Codi manufacturing produces high quality beverage canning equipment for small and large craft beverage producers at an affordable price. We offer solutions to all of your canning line needs including counterpressure fillers, depalletizers, twist rinses, pasteurizers, and custom conveyance.

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

There are two main methods for making beverage cans - the 2 piece can and the 3 piece can - and the manufacturing processes differs for each. 2 piece cans by far dominate the beverage industry, but 3 piece cans are still in use in some parts of the world, particularly for non-carbonated beverages. How a 3 piece can is made

Many New Aluminium Cans of Soda Soft Drink or Energy Drink Containers. Drinks Manufacturing

The Standard can is available in four classic sizes ranging from 12 oz. to 19.2 oz. It delivers the popular and familiar hand feel experience for consumers and is fully customizable — we offer the widest selection of enhancements, ends, filling options, and special effects in the industry Select Standard Sleek Condensed, still classic.

UK Manufacturing at a Glance Dean Group

With a large printable surface area and a wide range of sizes, shapes and decorating options, cylindrical aluminum beverage cans are the perfect packaging format to create a compelling brand presence where it counts - on the shelf in consumers' hands. Explore Decoration Options can-indoor Color-Changing Reactinks™ can-one-finish Visual Impact

(PDF) Manufacturing of soda cans omar khaled Academia.edu

English Beverage Can Line Stolle Machinery is the world's leading supplier of machinery for the production of two-piece can bodies for beer and other beverages. As a technology leader, Stolle provides proven equipment with the latest engineering advancements as well as OEM parts, service and rebuild services from facilities around the globe.

Many Aluminium Soda Drink Cans. Advertising for Soda Drinks or Tin Cans Mass Manufacturing Stock

Manufacturing process of a soda can and the materials involved: The manufacturing process of soda cans involves multiple stages, from raw material extraction to final packaging. Let's break down the process step by step: 1. Raw material extraction: The key raw materials used in soda can manufacturing are aluminum and steel.

The Coca Cola Supply Chain & Manufacturing Process Explained Dynamic Inventory

Bill details the engineering choices underlying the design of a beverage can He explains why it is cylindrical, outlines the manufacturing steps needed to created the can, notes why the can.